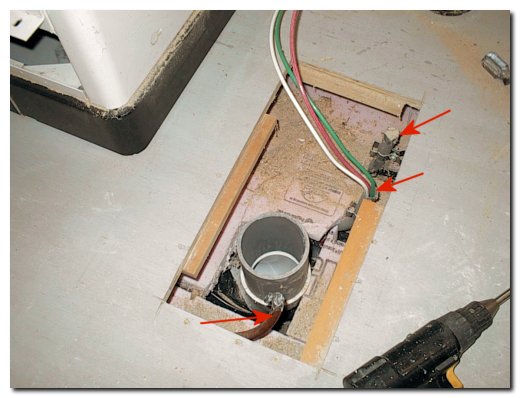

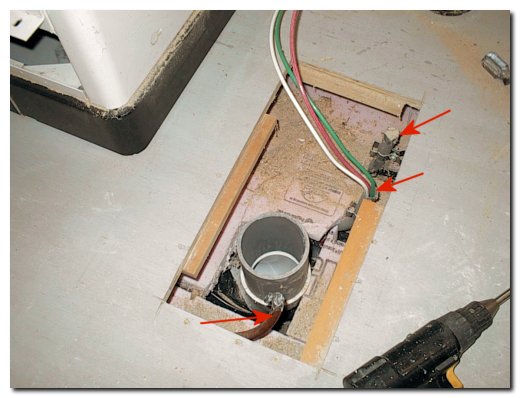

Today was my first opportunity to get back into the new shop and begin the process of setting it up and getting everything organized. The starting point was to get the table saw set up, this is the largest piece of equipment and has a lot of set-up required. When I roughed in the shop I located a 4 inch PVC conduit for the dust control system. You can see it in the hole in the floor along with two 3/4" EMT conduits and a 1/2" soft copper air line (lower arrow). I had pulled wire for the power to the table saw but had not spent a lot of time thinking about the way it was all going to work. If I had it to do over I would have located the 3/4 conduits more to the west (right side of opening) so they would not interfer with setting the table saw. I needed the 4" PVC under the saw and the counduits and air line on the outside of it.

So I added a couple off-sets in the 3/4 EMT and drilled a hole in the floor and moved the air line further to the north (bottom of picture). The red lines I put on the image show how the base of the saw will set over the 4" PVC. I removed a slanted metal plate from inside the table saw that was intended to direct the sawdust out a rectangular hole in the right side of the saw. I added a coupling to the 4" PVC so that it extended flush with the floor and then insulated around the conduit and other piping. Then I cut openings in the plywood flooring and screwed it in place. It was a simple matter to slide the saw over the dust control pipe and then fasten the saw down to the wood floor.

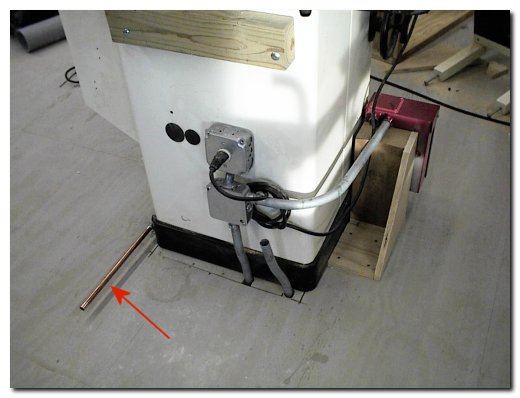

The picture above shows the finished wiring set-up for the table saw. I used a 4" square box on top of the 3/4 EMT and then more conduit to connect it to a panel that faces the front of the saw. To prevent any problems with access in the junction box I added another 4" sqare box above for the outlet that the saw plugs into. The other 3/4 EMT that is stubbed up will be used for control wiring for the dust control machine that will be located in the garage. You can also see the hard copper line I soldered to the soft copper to get it away from the table saw. This air line will extend to the underside of the counter I will build around the table saw.

The panel I used was left over from the old machine shed. It is a 4-circuit rain tight panel and although access to the breakers requires a hands and knees approach, it will keep dust from filling up the breakers as easily as an open panel would. I painted the panel red since it was pretty weatherd from its northern exposure on the old shed. I also added a 2-circuit outlet below the box. One of the openings will be used for the jointer that will set to the left of the table saw. At the end of the day I went outside to move the concrete around on the old foundation on the east side of the property. The piles were over three foot high and they would produce drifts high enough to close the road if I did not flatten them out.